Supply chain management (SCM) is no longer the exclusive domain of logistics experts. With increasing digitalization, software engineers are playing a pivotal role in transforming supply chain processes. Whether you’re a software engineer working on enterprise resource planning (ERP) systems, blockchain applications, or AI-driven analytics, understanding SCM is crucial to building solutions that drive efficiency and innovation.

In this comprehensive guide, we’ll explore everything software engineers need to know about supply chain management, from fundamental concepts to advanced technologies shaping the field.

What Is Supply Chain Management, and Why Is It Important?

At its core, supply chain management involves the coordination of all activities required to produce and deliver a product or service, from sourcing raw materials to delivering the final product to customers.

Key Processes Software Engineers Should Understand in SCM

While traditionally the domain of logistics and operations managers, SCM is increasingly dependent on robust software solutions for efficiency and innovation.

Procurement: Acquiring raw materials and goods.

- Focus on digital procurement platforms that automate supplier selection and contract management.

- Use APIs to integrate procurement data into broader SCM systems.

- Ensure compatibility with electronic data interchange (EDI) standards to streamline communications.

Production: Manufacturing and assembling products.

- Integrate production management systems (MES) with SCM platforms for real-time visibility.

- Leverage IoT for monitoring production lines and reducing downtime.

- Build tools to analyze production KPIs like yield rates and cycle times.

Distribution: Transporting goods to customers or retailers.

- Design route optimization algorithms to reduce transportation costs and delivery times.

- Include live tracking systems for shipment transparency.

- Build real-time notifications for delivery milestones or delays.

Inventory Management: Monitoring stock levels to meet demand.

- Use predictive analytics to anticipate demand and avoid overstocking.

- Implement barcode or RFID systems to automate stock tracking.

- Develop dashboards for warehouse managers to visualize inventory trends.

Modern SCM integrates technology at every step, making it highly relevant for software engineers. SCM systems should feature real-time monitoring, seamless integration with other enterprise systems, and robust scalability to adapt to fluctuating demands.

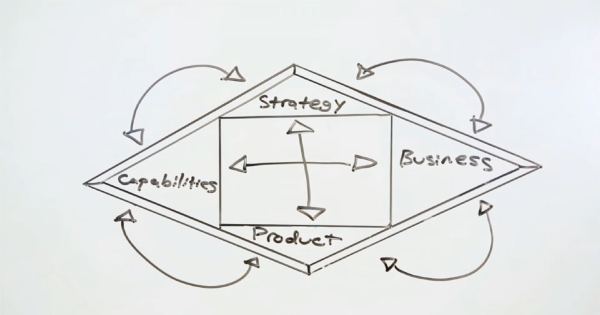

Almost every company faces the same software development challenges: knocking down silos to improve synergy between strategy, business, product and development capabilities

A Close-to-Home Example: The Supply Chain of a Software Company

The supply chain in a software company consists of a series of interconnected processes, from development to delivery and maintenance. Each phase relies on the efficient coordination of resources and teams to ensure smooth operations and timely product releases.

- Software Development

The supply chain begins with the software development process, where developers write and test code. This phase sets the foundation for everything that follows, as the quality and functionality of the software depend on the initial build. - Infrastructure and Tools

The development process is supported by the infrastructure and tools required for coding, version control, and deployment. Cloud platforms, development environments, and third-party APIs ensure that the software is scalable, secure, and ready for testing and production. - Talent Acquisition

To fuel the development and maintenance stages, companies must continuously acquire skilled talent. Effective recruitment strategies, including the use of nearshore or offshore teams, directly impact the speed and quality of product development. - Quality Assurance and Testing

Once the software is developed, it enters the testing phase. QA teams ensure that the software meets performance standards. The testing phase is tightly integrated with development, as bugs discovered during testing are quickly addressed, ensuring a seamless transition to the next stages. - Distribution Channels

After passing quality checks, the software is distributed via platforms like app stores or cloud-based systems. Distribution is linked with development, as the deployment process must be carefully planned to ensure smooth delivery and customer access to the product. - Customer Support and Maintenance

Once launched, ongoing maintenance is essential for keeping the software up to date and functional. Customer support teams address user issues, and regular updates are made based on feedback. This phase is directly tied to previous stages, as continuous improvements rely on the initial product and its ongoing testing. - External Partnerships and Licensing

Third-party services, such as hosting or integrations, often play a critical role in software functionality. These external elements integrate with the software, expanding its capabilities and ensuring smooth operation across different platforms.

Each stage of the supply chain is interconnected—issues in one area can affect the entire flow, making efficient coordination essential to successful software development and delivery.

Clayton Christensen’s key theories— Disruptive Innovation and Jobs-to-Be-Done—is essential for driving innovative thinking in software. These concepts help businesses navigate market disruption and make smarter product decisions. Photo by Meridian Magazine.

Why Supply Chain Knowledge Is Crucial for Software Engineers

For software engineers, SCM knowledge bridges the gap between technical expertise and business strategy. By understanding how supply chains operate, engineers can craft solutions that directly impact profitability and customer satisfaction.

Developers with stronger domain expertise in SCM create user-centric tools that drive tangible business outcomes.

4 Core Elements of Supply Chain Management for Building Smarter Systems

Understanding the core components of SCM is critical for designing effective software solutions. Each component represents a unique opportunity to streamline operations and improve efficiency.

Engineers should focus on ensuring scalability, data integration, and modularity to future-proof SCM components.

Top 3 Challenges in Supply Chains (and How Engineers Can Solve Them)

Supply chains face numerous challenges, from inefficiencies to security vulnerabilities due to sheer scale. Engineers play a vital role in overcoming these hurdles by developing innovative solutions.

To build better supply chain management systems, focus on solutions that promote transparency, collaboration, and agility.

Design for All Users: By prioritizing user needs and incorporating their insights, technical teams (product, design, and engineering) can create AR/VR applications that are not only technically sound but also intuitive, engaging, and ultimately, user-centric. Photo by Lucrezia Carnelos.

Cutting-Edge Technologies Transforming Supply Chain Management

The digital transformation of supply chains relies heavily on emerging technologies. These tools not only enhance efficiency but also provide the adaptability needed in today’s dynamic markets.

1. Artificial Intelligence (AI) for Efficiency

AI enhances demand forecasting, risk management, and supplier selection by identifying patterns in historical data.

- Build predictive models for demand forecasting and anomaly detection.

- Leverage AI for dynamic pricing optimization.

- Automate decision-making in inventory replenishment using machine learning.

2. Internet of Things (IoT) for Real-Time Monitoring and Analytics

IoT devices track shipments in real-time, providing transparency and accountability.

- Deploy IoT sensors for real-time asset tracking and condition monitoring.

- Build systems that notify stakeholders of delays or environmental risks.

- Use edge computing to process IoT data closer to its source for faster insights.

3. Blockchain for Transparency and Security

Blockchain ensures secure and tamper-proof records, useful for tracking goods and verifying transactions.

- Use distributed ledgers for tamper-proof supply chain data.

- Enhance transparency in multi-tier supplier networks.

- Implement smart contracts to automate compliance and payment.

4. Cloud Computing for Accessibility

Cloud-based SCM platforms allow teams to collaborate globally and access real-time data.

- Develop scalable platforms for SCM data storage and processing.

- Ensure global accessibility for distributed supply chain teams.

- Integrate multi-cloud solutions to avoid vendor lock-in.

5. Robotic Process Automation (RPA) for Focusing on Core Business

RPA automates repetitive tasks like order processing, freeing up human resources for more strategic work.

- Automate invoice processing and order tracking.

- Enable real-time updates for shipping and inventory statuses.

- Reduce manual intervention in demand forecasting.

The Role of Software Engineers in Modern Supply Chains

Software engineers contribute to SCM in various capacities, each with a specific focus on optimizing different aspects of the supply chain.

If you’re looking to build an international career building software for SCM, focus on roles that align with your technical strengths and contribute measurable value.

5 Proven Strategies for Optimizing SCM Solutions with Technology

Effective SCM solutions aren’t built overnight—they require continuous improvement and adaptability. Engineers play a pivotal role in this optimization process.

Regardless of your role, ensure the solutions are data-driven, user-friendly, and scalable to handle long-term business needs.

Leaders are constantly faced with tough decisions. Whether it’s a disruptive market shift, an underperforming product, or a new opportunity, deciding to pivot, patch, or persevere can be daunting. Photo by LinkedIn .

5 Emerging Supply Chain Trends Engineers Need to Watch in 2025

Staying ahead of trends ensures software engineers can build solutions that meet tomorrow’s supply chain needs.

1. Hyperautomation: Merging RPA, AI, and IoT in SCM

Hyper-automation combines AI, RPA, and IoT to automate every aspect of the supply chain.

- Combine RPA, AI, and IoT to automate end-to-end supply chain processes.

- Create event-driven architectures for faster decision-making.

2. Sustainability: Building Eco-Friendly Supply Chain Solutions

Engineers will play a crucial role in designing systems that track and reduce carbon emissions.

- Develop tools to measure and reduce carbon footprints across the supply chain.

- Build features for ESG (Environmental, Social, and Governance) reporting.

3. Augmented Reality (AR): Transformative Interactive Insights

AR is set to revolutionize warehouse operations by providing real-time visualizations of inventory.

- Enhance warehouse management by displaying stock locations in real-time.

- Improve worker training through immersive simulations.

- Improve warehouse operations with visual picking tools.

- Enable visual inspection of goods using AR overlays.

4. Digital Twins: Simulating Supply Chains for Real-Time Optimization

Digital twins create virtual replicas of supply chains to simulate scenarios and optimize operations.

- Build virtual models of physical supply chains to simulate changes and test scenarios.

- Use real-time IoT data to keep digital twins updated.

5. Building Resilient Systems for Uncertain Markets

The volatile nature of global markets demands resilient supply chains capable of withstanding disruptions. Building such systems involves preemptive strategies and robust technology.

- Focus on building supply chains that can withstand disruptions, like natural disasters or pandemics.

- Use AI for risk analysis to predict potential disruptions.

- Incorporate redundancy in critical supply chain components.

- Design fail-safe mechanisms to recover from unexpected failures.

Stay proactive in learning about these trends to future-proof your SCM solutions.

Software Engineers Are the Key to SCM Success

Remember, the future of SCM is in your hands—so keep learning, experimenting, and building systems that redefine how goods and services move across the globe.

Supply chain management is a complex, multifaceted domain, but software engineers are key to making it more efficient, transparent, and innovative. By understanding its components, embracing cutting-edge technologies, and addressing challenges, engineers can deliver high-impact solutions.

International Marketing Leader, specialized in tech. Proud to have built marketing and business generation structures for some of the fastest-growing SaaS companies on both sides of the Atlantic (UK, DACH, Iberia, LatAm, and NorthAm). Big fan of motherhood, world music, marketing, and backpacking. A little bit nerdy too!